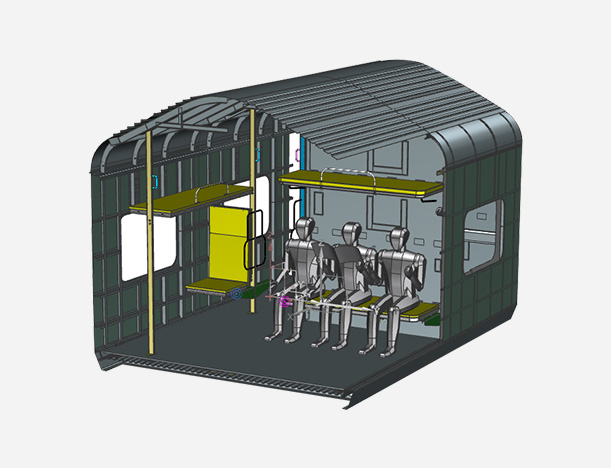

Engineering Design and Development

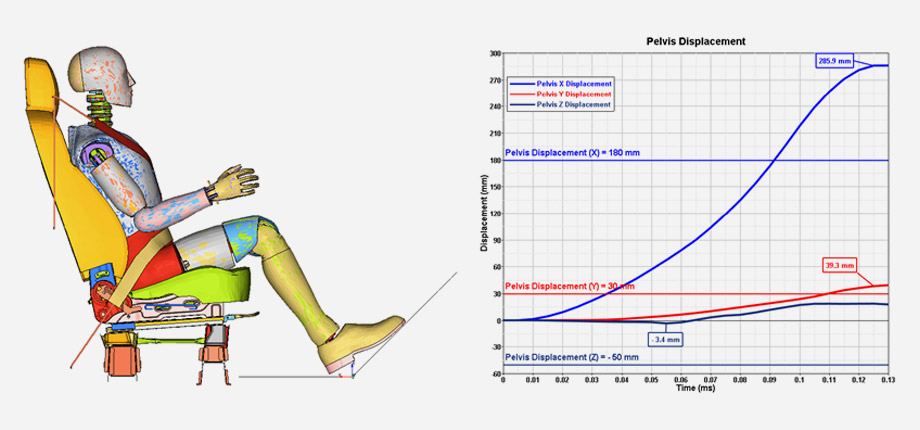

Over the last several years Bharat Seats Ltd has developed in-house capability to design, perform simulation, benchmark and develop prototypes. Our in-house testing and validation facility (NABL certified) enables us to do complete validation of the products. This lab is co-related with our customers and we can perform all important tests in-house. Our team continuously receives technology support and training from our Global Technology Partners that enables us to adopt latest technology in our products and processes.